Promotional Materials

In the beginning our promotional material consisted of a business card which had both my name and that of my partner on it. Within a year we each had our own business cards plus a small black and white pamphlet which explained our thoughts and approaches and had one picture of our work. By the end of year two we had a photo album that we “shared” with prospective clients. During year three we put out a professionally printed pocket folder type brochure. In the left pocket was an eight page booklet which contained the best thoughts we could come up with, and the right pocket held reprints of several articles I had written and several more of articles written about us and/or our work. They also had, on the front of one pocket, slotted inserts for the business card. It was all pretty pathetic, but our passion showed through and it connected with enough prospective clients to keep us busy enough to hire people and to begin actually taking real steps towards building a proper shop.

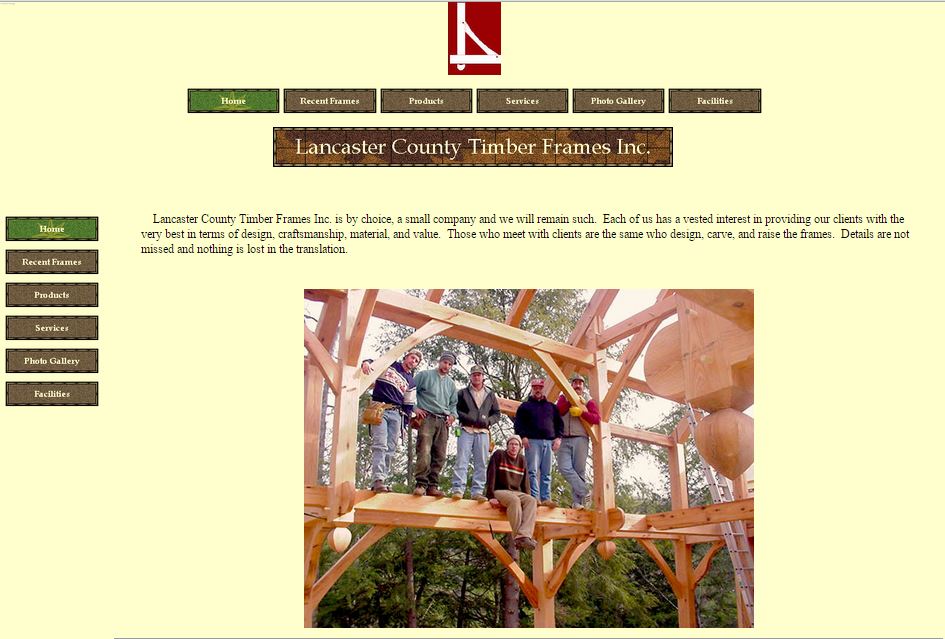

As the years passed the brochure grew in thickness, content and professionalism. Reproduction costs were just a bit shy of $20.00 per packet and postage ran about $6.00. We mailed out or handed out approximately 100 of these per year. We developed our first website in the mid-nineties – it was a two page website which would make a present-day second grader proud. During the coming years it grew and improved (pictured above) until we finally realized our limits and sought professional assistance (Lake Development Group, Inc). We consistently add to, subtract from and alter our web site. About six or so years ago we noticed that the traffic on the website was climbing steadily while the number of brochures being solicited dropped proportionately. I cannot remember when we last mailed a brochure, but it has to be several years now.

About a decade ago I was putting together a slide presentation of one of our projects to show at an upcoming guild conference. Of the ten photographs I selected, two were close-ups of joints, three were of the raising and five were of the completed and furnished structure. This exercise brought to mind something a girlfriend of mine during the early years commented when she looked through my photo album. Seeing only naked timber frames and close ups of joinery she said “This is structural pornography. Why are there no shots of the completed houses? Why are there no shots of furnished spaces?” She was right. I, as well as many of my colleagues back then, had tunnel vision.

Safety

I’m not 100% positive, but I’d still be willing to wager a large sum of money that during raisings prior to, let’s say, 1992, no timber framers in the United States wore fall protection. I am also willing to bet that if we were to practice timber framing today the way we did back then, OSHA would push real hard to add death to their stable of penalties. Not only was fall protection not on our radar, but we also didn’t wear hard hats or approved foot wear at raisings, nor did we wear safety glasses in the shop. And I remember well that several of our electric cords were beyond repair. The slings that we used to pull the frame members together during pre-fitting in our shop were unrated. The heavy duty come-alongs we used to pull everything together were equipped with thin tubed break away handles to prevent overloading the mechanism – of course we replaced such handles with thick non-breakable aluminum ones which we fashioned ourselves. The list goes on and on.

Back in the day, we invited clients to spend a day, or days, with us in the shop to work along side of us carving their frame. We tried to match their tasks to their skill level and were always careful not to let them work on things that were critical or difficult or dangerous. Not always, but more often than not, it slowed us down. It was a small price to pay since their passion fueled ours. In almost every case we invited the clients to participate in the raising of their frame. I cannot remember one time that such raisings were not a highly pleasurable event. This practice stopped when we were able to afford insurance policies and when we began to read OSHA regulations. Due to lack of funds, we didn’t use scaffolding for the first five years or so. Other than when we could climb on the frame, everything was done on ladders, often at those top rungs which were marked DO NOT STAND. Fall protection was Vibram® soles and a firm grip. Except for the passing of the client involvement, I don’t miss any of the stupidity we practiced in our dark past.

Fifty Shades of Bald

When I first got involved with timber framing twenty six years ago I was forty years old. Almost all of my fellow timber framers back then were also close to that benchmark. I feel very safe in stating that, with maybe one exception, all of us who started in the seventies or eighties came to timber framing from other disciplines, professions or careers. Now, those of us who still have hair have little if any pigment. But what we do have is pride and relief that young people are entering the field. For a number of years I feared that we were becoming a club of old men. Thanks in no small part to the Timber Frames Guild’s effort in setting up and administering an apprenticeship program and the American College of the Building Arts in South Carolina offering a BS in Applied Science with a major in timber framing it appears that such fear is now baseless.

– Tony Zaya