[av_one_full first min_height=” vertical_alignment=’av-align-top’ space=” row_boxshadow=” row_boxshadow_width=’10’ row_boxshadow_color=” custom_margin=” margin=’0px’ av-desktop-margin=” av-medium-margin=” av-small-margin=” av-mini-margin=” mobile_breaking=” mobile_column_order=” border=” border_style=’solid’ border_color=” radius=” min_col_height=” padding=” av-desktop-padding=” av-medium-padding=” av-small-padding=” av-mini-padding=” svg_div_top=” svg_div_top_color=’#333333′ svg_div_top_width=’100′ svg_div_top_height=’50’ svg_div_top_max_height=’none’ svg_div_top_flip=” svg_div_top_invert=” svg_div_top_front=” svg_div_top_opacity=” svg_div_top_preview=” svg_div_bottom=” svg_div_bottom_color=’#333333′ svg_div_bottom_width=’100′ svg_div_bottom_height=’50’ svg_div_bottom_max_height=’none’ svg_div_bottom_flip=” svg_div_bottom_invert=” svg_div_bottom_front=” svg_div_bottom_opacity=” svg_div_bottom_preview=” column_boxshadow=” column_boxshadow_width=’10’ column_boxshadow_color=” background=’bg_color’ background_color=” background_gradient_direction=’vertical’ background_gradient_color1=’#000000′ background_gradient_color2=’#ffffff’ background_gradient_color3=” src=” background_position=’top left’ background_repeat=’no-repeat’ highlight=” highlight_size=” animation=” animation_duration=” animation_custom_bg_color=” animation_z_index_curtain=’100′ parallax_parallax=” parallax_parallax_speed=” av-desktop-parallax_parallax=” av-desktop-parallax_parallax_speed=” av-medium-parallax_parallax=” av-medium-parallax_parallax_speed=” av-small-parallax_parallax=” av-small-parallax_parallax_speed=” av-mini-parallax_parallax=” av-mini-parallax_parallax_speed=” css_position=” css_position_location=” css_position_z_index=” av-desktop-css_position=” av-desktop-css_position_location=” av-desktop-css_position_z_index=” av-medium-css_position=” av-medium-css_position_location=” av-medium-css_position_z_index=” av-small-css_position=” av-small-css_position_location=” av-small-css_position_z_index=” av-mini-css_position=” av-mini-css_position_location=” av-mini-css_position_z_index=” link=” linktarget=” link_hover=” title_attr=” alt_attr=” mobile_display=” mobile_col_pos=’0′ id=” custom_class=” template_class=” aria_label=” av_uid=” sc_version=’1.0′]

[av_image src=’https://lancotf.com/wp-content/uploads/2024/05/KimberLee-9-1030×707.jpg’ attachment=’9068′ attachment_size=’large’ copyright=” caption=” image_size=” styling=” box_shadow=’none’ box_shadow_width=’10’ box_shadow_color=” align=’center’ font_size=” overlay_opacity=’0.4′ overlay_color=’#000000′ overlay_text_color=’#ffffff’ link=” target=” animation=’no-animation’ animation_duration=” animation_custom_bg_color=” animation_z_index_curtain=’100′ parallax_parallax=” parallax_parallax_speed=” av-desktop-parallax_parallax=” av-desktop-parallax_parallax_speed=” av-medium-parallax_parallax=” av-medium-parallax_parallax_speed=” av-small-parallax_parallax=” av-small-parallax_parallax_speed=” av-mini-parallax_parallax=” av-mini-parallax_parallax_speed=” hover=” blur_image=” grayscale_image=” fade_image=” appearance=” css_position=” css_position_location=’,,,’ css_position_z_index=” av-desktop-css_position=” av-desktop-css_position_location=’,,,’ av-desktop-css_position_z_index=” av-medium-css_position=” av-medium-css_position_location=’,,,’ av-medium-css_position_z_index=” av-small-css_position=” av-small-css_position_location=’,,,’ av-small-css_position_z_index=” av-mini-css_position=” av-mini-css_position_location=’,,,’ av-mini-css_position_z_index=” transform_perspective=” transform_rotation=’,,,’ transform_scale=’,,’ transform_skew=’,’ transform_translate=’,,’ av-desktop-transform_perspective=” av-desktop-transform_rotation=’,,,’ av-desktop-transform_scale=’,,’ av-desktop-transform_skew=’,’ av-desktop-transform_translate=’,,’ av-medium-transform_perspective=” av-medium-transform_rotation=’,,,’ av-medium-transform_scale=’,,’ av-medium-transform_skew=’,’ av-medium-transform_translate=’,,’ av-small-transform_perspective=” av-small-transform_rotation=’,,,’ av-small-transform_scale=’,,’ av-small-transform_skew=’,’ av-small-transform_translate=’,,’ av-mini-transform_perspective=” av-mini-transform_rotation=’,,,’ av-mini-transform_scale=’,,’ av-mini-transform_skew=’,’ av-mini-transform_translate=’,,’ mask_overlay=” mask_overlay_shape=’blob’ mask_overlay_size=’contain’ mask_overlay_scale=’100%’ mask_overlay_position=’center center’ mask_overlay_repeat=’no-repeat’ mask_overlay_rotate=” mask_overlay_rad_shape=’circle’ mask_overlay_rad_position=’center center’ mask_overlay_opacity1=’0′ mask_overlay_opacity2=’1′ mask_overlay_opacity3=” title_attr=” alt_attr=” img_scrset=” lazy_loading=’disabled’ id=” custom_class=” template_class=” av_element_hidden_in_editor=’0′ av_uid=’av-lvznh94z’ sc_version=’1.0′ admin_preview_bg=”][/av_image]

[/av_one_full][av_hr class=’default’ icon_select=’yes’ icon=’ue808′ position=’center’ shadow=’no-shadow’ height=’50’ custom_border=’av-border-thin’ custom_width=’50px’ custom_margin_top=’30px’ custom_margin_bottom=’30px’ custom_border_color=” custom_icon_color=” av-desktop-hide=” av-medium-hide=” av-small-hide=” av-mini-hide=” id=” custom_class=” template_class=” av_uid=” sc_version=’1.0′]

[av_textblock textblock_styling_align=” textblock_styling=” textblock_styling_gap=” textblock_styling_mobile=” size=” av-desktop-font-size=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” font_color=” color=” id=” custom_class=” template_class=” av_uid=’av-lvzeuo8d’ sc_version=’1.0′ admin_preview_bg=”]

Quality Material-

One important aspect leading to a successful timber frame project is the quality of the material. These qualities include such attributes as Species, Grade, Moisture Content, Milling, and Surfacing. Not only do they contribute to the final appearance of the timber frame, they also impact the bottom line along with cost, value, quality, and lead-time as a natural consequence of these specifications.

Species-

We love Douglas Fir for timber framing. Of all the timber species, it has the best combination of strength, high grades, long lengths, dimensional stability, and availability. Nearly all of the frames we produce are made with this material and we find it to be the best value for a long lasting, stable timber frame.

White Oak is also a traditional species for timber framing on the East Coast. Although it has great strength values, White Oak is much less available in long lengths and higher grades. It is also known for its significant shrinkage, twisting, and checking due as a result of drying or seasoning. This often means that the joinery that looked amazing when cut and assembled but not quite so awesome after it has reached a more stable moisture content. Many of our customers desire this authentic display of natural seasoning and embrace the more rustic appearance of White Oak.

Southern Yellow Pine is a close second to Douglas Fir but it is generally not as strong and high grades are less available in large sizes and lengths. It tends to be very “sappy” and sticky while working with it and occasionally can exhibit discoloration due to a blue stain fungus endemic to this species.

Eastern White Pine is locally available and very affordable but has low strength values and length limitations. Generally, the timber sizes need to be larger since the wood is not as strong as other species. Eastern White Pine also tends to shrink and check more than Douglas Fir. There is also a persistent pattern of dark knots that can be visually jarring due to the stark color contrast and frequency.

Grade-

The “grade” refers to the quality of the wood and is determined primarily by the size and frequency of knots and the slope of grain. The higher the grade, the fewer and smaller the knots on each face. Structurally, the knots create stress concentrations and opportunity for weakness in the wood and so less knots means stronger timbers. Aesthetically, the knots are generally not preferable and can sometimes tear out during the planing process, leaving voids in faces and corners that need to be filled or patched in the finishing stage of production. Wane, or the presence of bark on the edges of the timber, is another criteria affecting grade but rarely a deciding factor. Grades typically available are: #2 and better, #1 and better, or Select Structural, in ascending order based on strength values. Douglas Fir is the only species that is reliably available in Select Structural grade which is another reason that we love it.

Moisture Content- Kiln Dried vs. “Green”

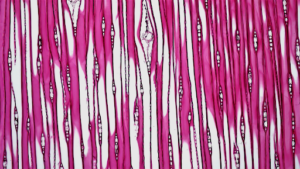

The cellular structure of a tree is essentially a bundle of straw-shaped cells that transfers water and nutrients between the roots and the leaves (or needles). As soon as a tree is cut and the wood begins to dry out, the moisture that was previously traveling up and down the tree begins to escape, primarily from the ends of the wood grain. As the moisture in the wood evacuates, the cells flatten out and the cross section of the wood begins to contract or shrink. This is not a problem until the log gets milled to a particular timber size, at which point, the timber framer is expecting to be able to exercise his craft and fit the joinery together. Unfortunately, if there is still moisture in the wood fibers, they will continue to dry and shrink, causing the joinery that once fit perfectly to look less than excellent. The amount of shrinkage has a direct and well understood correlation to the change of moisture content in the wood. Ultimately, the timber frame will reach a point of equilibrium where it is no longer losing moisture and, outside of some seasonal changes, will remain dimensionally stable. Relative to most of the other species available, Douglas Fir comes to us with a low moisture content and consequently, the joinery we cut in our shop stays looking nice for longer. In softwoods such as Douglas Fir and Southern Yellow Pine, it is possible to specify Kiln-Dried timber material which accelerates the drying process to further increase the dimensional stability of the timbers.

Milling-

Related to moisture content, the “milling” of a timber is another specification that has an effect on the final appearance of a timber frame. A square timber is cut from a round log and the part of the tree’s cross section within the cut of the timber has a big impact on its dimensional stability. As the straw-shaped cells dry out and get skinnier, the shrinkage creates tension between the cell walls which eventually separate, leading to a split that runs parallel to the wood grain known as a “check”. Checks tend to radiate out from the “heart” or center of the tree and are the widest at the surface of the timber. Interestingly, where the heart of the tree is not in the cut of the timber, the tension between the cell walls is not nearly as extreme and therefore, the checking is less frequent and much smaller. A timber that is “Free of Heart Center” or “FOHC” has a cleaner appearance and is less prone to twisting and checking.

Surfacing-

Surfacing-

Most of the timber that is used for Timber Frame construction is sawn to its rough dimensions on either a Circular Saw mill or a Band Saw mill. Quite often, the timbers are then planed on all four sides (S4S) by a four-sided planer which produces a “square” and “true” timber. The term “square” refers to precision of the 90 deg. corners and “true” refers to whether the opposite faces are parallel and equal. All of this matters when it comes time to cut and fit the mortise and tenon joinery. When timbers are not surfaced well, the joinery is difficult to fit and has a direct impact on the quality or the cost of the project. Starting with precisely surfaced timbers allows for excellent fitting joinery with minimum effort by the craftsman.

Quality Material-

There are many factors to consider when choosing the material for a new timber frame Choosing the right Species and Grade with the desired Moisture Content, Milling, and Surfacing is an important first step. Here at Lancaster County Timber Frames, we will work with you on selecting the highest quality materials, ensuring a great looking timber frame that will last for years to come.

[/av_textblock]

[av_image src=’https://lancotf.com/wp-content/themes/enfold/config-templatebuilder/avia-template-builder/images/placeholder.jpg’ copyright=” caption=” image_size=” styling=” box_shadow=’none’ box_shadow_width=’10’ box_shadow_color=” align=’center’ font_size=” overlay_opacity=’0.4′ overlay_color=’#000000′ overlay_text_color=’#ffffff’ link=” target=” animation=’no-animation’ animation_duration=” animation_custom_bg_color=” animation_z_index_curtain=’100′ parallax_parallax=” parallax_parallax_speed=” av-desktop-parallax_parallax=” av-desktop-parallax_parallax_speed=” av-medium-parallax_parallax=” av-medium-parallax_parallax_speed=” av-small-parallax_parallax=” av-small-parallax_parallax_speed=” av-mini-parallax_parallax=” av-mini-parallax_parallax_speed=” hover=” blur_image=” grayscale_image=” fade_image=” appearance=” css_position=” css_position_location=” css_position_z_index=” av-desktop-css_position=” av-desktop-css_position_location=” av-desktop-css_position_z_index=” av-medium-css_position=” av-medium-css_position_location=” av-medium-css_position_z_index=” av-small-css_position=” av-small-css_position_location=” av-small-css_position_z_index=” av-mini-css_position=” av-mini-css_position_location=” av-mini-css_position_z_index=” transform_perspective=” transform_rotation=” transform_scale=” transform_skew=” transform_translate=” av-desktop-transform_perspective=” av-desktop-transform_rotation=” av-desktop-transform_scale=” av-desktop-transform_skew=” av-desktop-transform_translate=” av-medium-transform_perspective=” av-medium-transform_rotation=” av-medium-transform_scale=” av-medium-transform_skew=” av-medium-transform_translate=” av-small-transform_perspective=” av-small-transform_rotation=” av-small-transform_scale=” av-small-transform_skew=” av-small-transform_translate=” av-mini-transform_perspective=” av-mini-transform_rotation=” av-mini-transform_scale=” av-mini-transform_skew=” av-mini-transform_translate=” mask_overlay=” mask_overlay_shape=’blob’ mask_overlay_size=’contain’ mask_overlay_scale=’100%’ mask_overlay_position=’center center’ mask_overlay_repeat=’no-repeat’ mask_overlay_rotate=” mask_overlay_rad_shape=’circle’ mask_overlay_rad_position=’center center’ mask_overlay_opacity1=’0′ mask_overlay_opacity2=’1′ mask_overlay_opacity3=” title_attr=” alt_attr=” img_scrset=” lazy_loading=’disabled’ av-desktop-hide=” av-medium-hide=” av-small-hide=” av-mini-hide=” id=” custom_class=” template_class=” av_element_hidden_in_editor=’0′ av_uid=” sc_version=’1.0′][/av_image]