Contracts

For the first decade of business all our contracts were hand written calligraphically by me. At first they were simply one page but eventually they grew to a page and a half. Had they been typed the longest would have taken required three quarters of a page. I’m not sure how this compared to those of most timber frame companies so I won’t speculate. But I do remember seeing contracts from maybe two dozen other companies and the length, if not the content, was pretty much the same. I no longer do the calligraphy thing, not so much because our contracts today are much longer, which indeed they are, but because changes are so very easy to effect with the computer. I used to hold some disdain for contracts that were long and heavy in legalese. But I have come to see that a tool of communication and a means of memorializing expectations and responsibility. Well executed, I now see a contract, not necessarily as a poem, but a strong attempt at perfect communication.

False Purity

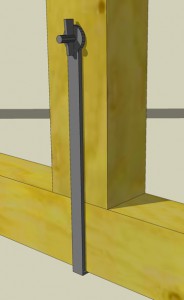

In the early years there existed a group think which held that only mortise & tenon joinery (I’ll include also dovetails and scarfs in that group) were the only pure manner of connecting wooden members in a “true” timber frame. Steel brackets and hangers were blasphemy. Admittedly, the mass produced steel connectors readily available back then were pretty much devoid of any aesthetic quality. Such steel connectors were considered “short- cut” connections.

As time passed two things happened. One, we kept pushing the limits of what we asked wood to do – spans increased, intersections became more complex. There are limits to what a mortise and tenon joint can handle, particularly in tension. Steel, exposed or hidden, can solve a lot of problems. Two, as many looked to history we found compelling evidence that the old timers often employed iron when it was needed and when it could be afforded. Almost all of the really old examples which I found were hand wrought and most often elegant features. This one is from an early 1800’s Quaker meetinghouse. There may still be some timber framers who avoid iron or steel at all costs and I would guess that they are also avoiding long spans and high tension joints. Most of us realize there are pragmatic as well as aesthetic reasons for employing iron and steel. However, if a client objects from a visual perspective yet steel is structurally necessary at a joint, most of us can handle a concealed steel spline. At this point in time I see very little residue of restrictive dogma within the timber framing community.

Public Awareness

Even as late as the mid 1980’s the term timber framing was unknown to the vast majority of people. When we tried to explain what it was, people usually stopped us before we could complete a sentence and said “You mean like a log cabin.” If I’ve heard this response once, I’ve heard it hundreds of times. But, not so much lately. In fact, I probably haven’t heard it in the last decade. Public awareness really expanded in the 1990’s due to the effort of the Timber Framers Guild and the Timber frame Business Council, television coverage (probably beginning with the Habitat For Humanity guild project in 1989), the dozen or so books on timber framing that have been published since the revival began, the numerous magazine and newspaper articles that have appeared and the individual efforts of all timber framers.

I can remember dreaming in the early years of having the opportunity of carving a commercial project – if I could only get commercial project architects to see the possibilities…. In the past sixteen years we have done over fifty. In this number are churches, restaurants, museums, golf course club houses, wineries, visitors’ centers and lodges. Included in this group are The Gettysburg National Battlefield and Museum; The Great Harbor Yacht Club of Nantucket; Kinsley’s Shoprite (the world’s largest Shoprite); the Siegrist Mill Burr Arch covered bridge in Pennsylvania; the River Company Restaurant & Brewery in Radford, Virginia; St. Mary’s WorshipCenter in Johnson City, Tennessee; and the Belmont Abbey Chapel in North Carolina.

While we in this craft would like to take a modicum of credit for expanding public awareness and utilization of timber framing, we do need to admit that it was, in many ways, an easy sell. To begin with, timber framing had a long diverse history. For more than seven thousand years this method of construction has served mankind well. No country or culture can claim it as its own as it was practiced on all land parts of the earth where trees were available. Another plus for timber framing is that it is a construction method not an architectural style. The final look or feel or presence of the structure is determined by the manner in which the designer manipulates those elements within his control.

Unlike iron or steel or masonry or glass, wood is warm, it is inviting and it almost begs to be touched. And the skeletal structure that is the result of joining the timbers together is, at its essence, structural sculpture – a piece of art that has a pragmatic function. You just don’t get better than that.

– Tony Zaya

[/et_pb_text][/et_pb_column][/et_pb_row][et_pb_row][et_pb_column type=”1_2″][et_pb_blurb admin_label=”Blurb” title=”Part 4″ url=”/changes-in-timber-frame-industry-part-4″ url_new_window=”off” use_icon=”on” font_icon=”%%31%%” icon_color=”#7EBEC5″ use_circle=”off” circle_color=”#7EBEC5″ use_circle_border=”off” circle_border_color=”#7EBEC5″ icon_placement=”top” animation=”top” background_layout=”light” text_orientation=”center” use_icon_font_size=”off” use_border_color=”off” border_color=”#ffffff” border_style=”solid”] [/et_pb_blurb][/et_pb_column][et_pb_column type=”1_2″][et_pb_blurb admin_label=”Blurb” title=”Part 6″ url=”/changes-in-timber-frame-industry-part-6″ url_new_window=”off” use_icon=”on” font_icon=”%%32%%” icon_color=”#7EBEC5″ use_circle=”off” circle_color=”#7EBEC5″ use_circle_border=”off” circle_border_color=”#7EBEC5″ icon_placement=”top” animation=”top” background_layout=”light” text_orientation=”center” use_icon_font_size=”off” use_border_color=”off” border_color=”#ffffff” border_style=”solid”] [/et_pb_blurb][/et_pb_column][/et_pb_row][/et_pb_section]